Solving 3D Visualization Challenges with KiPcreating’s Expressa Aircraft Configurator

Introduction

Private aviation clients today expect a fully bespoke cabin-design experience – but also demand it faster and more flexibly than ever before. Where it once took weeks to produce final interior renderings, today’s buyers want to explore materials, color schemes, and layouts on the fly, with every change reflected immediately in ultra-realistic visuals. Traditional 3D pipelines struggle to keep up: producing a typical business-jet interior package of five images, a specs book and animations can take 2-5 weeks, leaving little room for rapid iteration and clearly losing momentum with the customer. This gap between client expectations and existing workflows has driven a digital transformation in cabin design. KiPcreating’s Expressa Aircraft Configurator was built to meet these needs – a real-time, photorealistic configurator that lets even non-technical users design and visualize customized aircraft interiors in minutes. By instantly rendering high-fidelity scenes “in minutes, not days”, Expressa empowers OEM, completion center and MRO design teams to stay agile, accurate and competitive in the Business Aviation market.

Persistent Visualization Challenges

Material Realism & Color Scheme Fidelity

For visualization teams and designers, getting materials and colors right is critical – but notoriously difficult. Under traditional workflows, a color chosen on-screen may look dull or overly saturated in a final render, and subtle material cues (like leather grain or brushed-metal gleam) can be lost or misrepresented. Design collaborators frequently need multiple rounds of tweaking to nail the exact look. This mismatch not only wastes time but risks mistakes: a client-approved fabric might appear different in the real cabin than in renderings, damaging confidence.

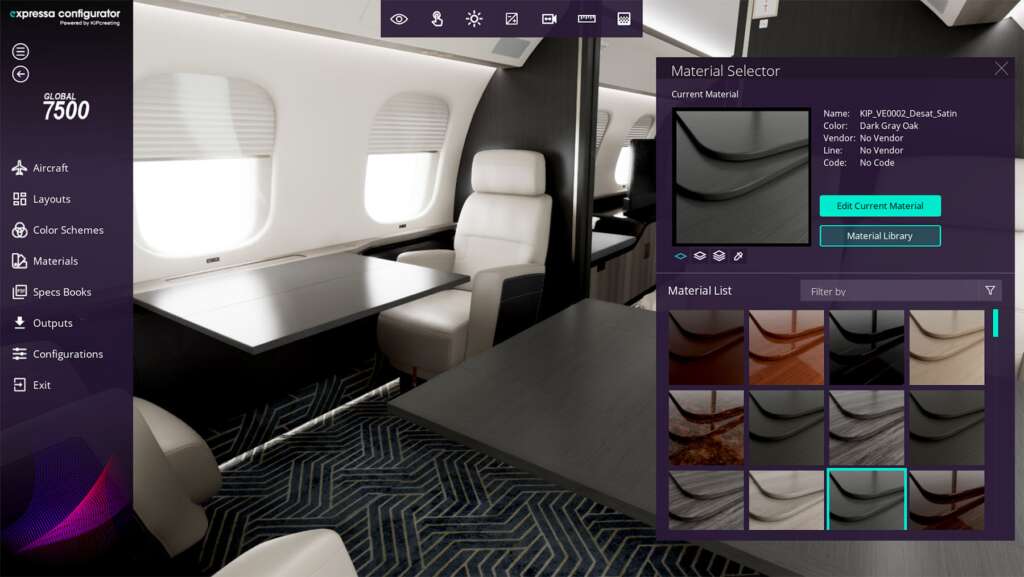

The Expressa Aircraft Configurator tackles this head-on with real-time, physically-based rendering (PBR) and a curated material library. In the render below, for example, the interplay of natural light on leather upholstery, carpet fiber and polished wood is captured with astonishing accuracy. All textures in Expressa are based on true-to-life PBR assets, so designers see the real appearance of each surface immediately. A constantly growing cloud library lets teams share and apply fully editable, high-fidelity material swatches enterprise-wide. Moreover, Expressa Configurator enforces brand-approved templates for colors and finishes: every cabin palette can be locked down to approved Pantone or RGB values, so that no one inadvertently strays from corporate design standards. In practice, this means 3D teams no longer guess at how a new finish will photograph. Any change to a material in the Expressa Configurator automatically updates all viewpoints, giving designers confidence that the on-screen colors will match the eventual aircraft interior. The result is faster, more accurate decision-making and far fewer color-related revisions.

Leather stitch lines and fabric texture respond dynamically to scene lighting, ensuring what designers see on-screen matches the real product.

Workflow Integration with Evolving Design Decisions

Aircraft interior projects are highly collaborative and iterative. A cabin layout might be updated by the engineering team, a lighting concept changed by the design lead, or a client request a new wood veneer—all often in parallel. In a siloed pipeline, each of these changes typically means clashing files and manual rework. For example, a mid-project shift in seat arrangement might require re-modeling, re-UV mapping and re-lighting the entire scene, with 3D artists scrambling to realign assets. These handoffs introduce delays and errors; important updates sometimes slip through the cracks.

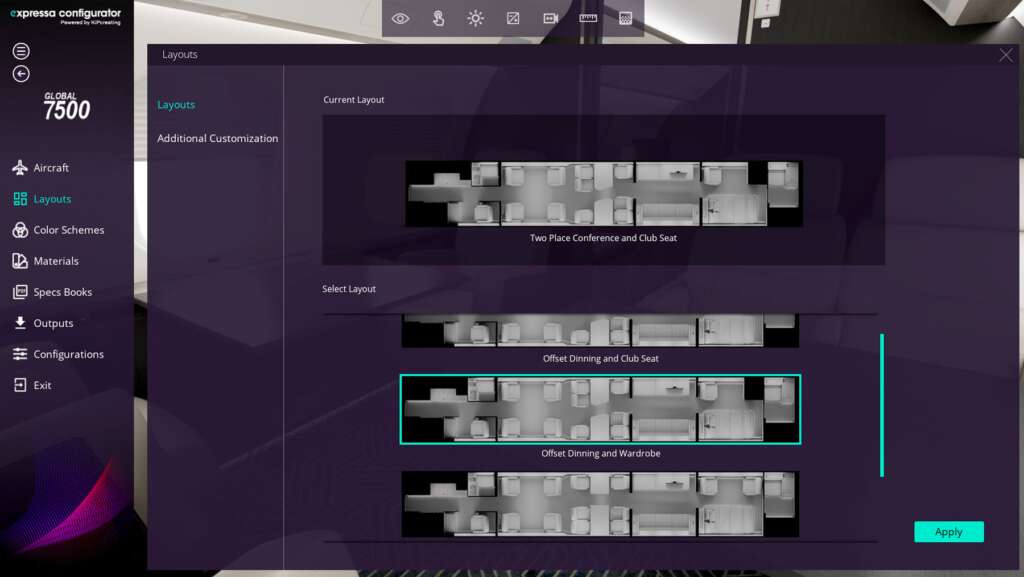

Expressa Configurator unifies the process by giving every stakeholder access to the same intuitive UI and shared asset library. Designers, marketers and even salespeople can log in to the configurator – no specialized 3D skills needed – and apply design changes on the fly. A library of pre-configured cabin templates (including cameras, cabin layouts and component groups) means that any adjustment to geometry or content propagates consistently. For example, approved material updates (say a new leather grain) flow instantly to every affected model. Since all data is tied to centrally managed assets, one change is reflected in all renderings and animations. Teams can “create, store, edit, and share” configurations in real time, eliminating batch hand-offs. In practice, this seamless integration lets teams experiment and iterate freely: a design revision enacted in a morning meeting shows up in fully updated, photorealistic renders by afternoon, without a cumbersome file-trading cycle.

In the case that an MRO already has an internal team of 3D artists, The Expressa Configurator empowers them to build interiors and produce visualizations up to 10 times faster than traditional 3D modelling software. Allowing them to make faster changes to colors and materials throughout the cabin. The KiPcreating team can even act as an extension of the internal team, collaborating to make custom changes to cabin assets faster. Cutting down on process bottle necks, delays, quality inconsistencies and streamlining the overall customer experience across all aircraft cabin projects.

Lengthy Review and Approval Cycles

A major bottleneck in traditional workflows is the slow back-and-forth of reviews. Typically, 3D artists produce a batch of static images or animations and send them for feedback. Clients and executives then markup PDF slides or delay approval while waiting for the next set of renders. Each round might take days, and important feedback (like “show this fabric in daylight” or “move that curtain left”) triggers a repeat of the lengthy render cycle. This ping-pong can drag decision-making for weeks and drive-up costs and rework fatigue.

Expressa Aircraft Configurator dramatically shortens these cycles by turning every review into an interactive session. Stakeholders can view the actual configurator on a laptop – manipulating materials, textures and layouts live. Any requested tweak is visible in real time. Furthermore, Expressa automatically generates deliverables on demand. As the press release notes, the platform “helps retain leads by automatically creating spec books, customer brochures, and estimates on the spot”. In other words, while the design team reviews a configuration, Expressa Configurator is already exporting high-resolution images, and updated spec documents, all with the new choices baked in. This immediacy means clients see exactly what they want without waiting overnight for renders. Feedback loops become measured in minutes instead of days. The streamlined experience not only cuts production time by orders of magnitude but also keeps internal and external reviewers engaged – everyone sees the next iteration before walking out of the meeting.

Because adjustments (like alternative carpet or cabinet styles) are rendered in real time, project teams can iterate instantly. Automated exports of each variant (images, layouts) mean design approvals no longer require repeated, time-consuming render passes.

Geometry-Driven Changes Affecting the Entire Scene

Even beyond materials, structural layout changes have long plagued cabin visualization. When interior architects alter a wall position, add a galley module or change seat tracks, the ripple effects are massive. A small geometry tweak in an offline pipeline typically forces 3D artists to rebuild portions of the scene, reassign materials, and re-position all lighting. Each dependent asset and camera may need manual adjustment. This fragility causes teams to lock down designs too early or push changes to the very end, neither of which is ideal in a customization-focused market.

KiPcreating supports these changes in geometry by working with internal customer 3D Teams to create or modifying specific 3D assets that accurately represent feasible engineering outcomes in a customer aircraft. These assets are developed in close collaboration with the MRO’s engineering team and precisely integrated into the aircraft model. Once modeled and correctly positioned, the new components become customizable in the Expressa Configurator, just like standard elements. A one-time implementation fee applies per asset, and ownership remains with the subscribing company for as long as they use the Expressa Configurator.

Once assets are implemented in the Expressa Configurator model, the software is able to dynamically recalculate related placements and lighting in real time. Importantly, approved templates enforce design rules: for instance, moving a divider also shifts associated floor trim and window treatments together, preserving alignment and sightlines. Because every object references the same parametric setup, there is no need to rebuild the model from scratch after each change. The cabin lights will then update to avoid any unwanted shadows or reflections of the new asset. In short, the Expressa Configurator makes the entire 3D model responsive. Designers can experiment with radical layout changes without breaking the process, knowing the engine will “transform complex 3D workflows into an effortless process”. This adaptability accelerates engineering-design feedback and allows creative solutions that would have been too risky under the old, rigid pipeline.

Geometry changes update instantly in Expressa Configurator. In this scene, a business jet cabin is shown under nighttime lighting. When switching to daytime, Expressa automatically recalculates the lighting conditions in real time, allowing materials to be viewed accurately under different light scenarios—without needing to rebuild the scene.

Business Impact and Operational Efficiency

The advantages of these features translate into dramatic business benefits. Users of Expressa report orders-of-magnitude gains in speed and cost-efficiency. In fact, the platform delivers up to 97× faster content production and roughly 95% reduction in production costs compared to conventional CGI workflows. Practically speaking, what used to take weeks now takes minutes. Design and marketing teams can produce a whole deck of photoreal cabin images in the time it previously took to render one.

- Unmatched Efficiency: By compressing the timeline of 3D visualization, Expressa Configurator enables nearly 97× faster outputs and roughly 95% lower costs. A full interior presentation (images & layouts) can be generated in minutes instead of the multiday process of legacy tools. This slashes production budgets and empowers companies to explore more design options without penalty.

- Brand Consistency: Centralized libraries and templates guarantee every output adheres to brand standards. Approved colors, materials and camera setups mean that even if different users or departments generate renderings, the result looks uniform and on-brand. This consistency reduces costly rework when a visualization doesn’t match corporate guidelines.

- Streamlined Collaboration: The intuitive, unified interface breaks down silos between design, sales, and marketing teams. Teams share one source of truth (assets and configurations in the cloud), so hand-offs are virtualized. Designers aren’t trapped in a rendering bottleneck, and salespeople can create simple 3D configs themselves. This alleviates reviewer fatigue: routine tasks are automated, letting human talent focus on creativity and client engagement.

- Shortened Feedback Loops: Real-time interactivity means decisions happen faster. Clients and executives see revisions immediately, and automated deliverables (renders, spec sheets, animations) are ready on the spot. In practice, project reviews that once took weeks now wrap up in days or hours. This agility accelerates time-to-market – new cabin variations can launch with fresh visuals almost as quickly as design meetings conclude.

- Enhanced Client Experience: The configurator creates a powerful “wow” factor in sales and marketing. Potential buyers can virtually explore every trim option, boosting engagement. As KiPcreating’s CEO Max Pardo emphasizes, the Expressa Configurator lets teams “deliver captivating customer experiences at a fraction of the cost”. In short, clients feel like co-designers, leading to better alignment and higher satisfaction.

Together, these impacts give aviation OEMs, completion centers and MROs a tangible competitive edge. Firms can offer vastly more personalized options with less effort, and launch interior updates more frequently. The combination of speed, quality and interactivity ultimately translates into more wins: faster deals, smoother marketing campaigns, and stronger brand perception in the high-stakes VVIP segment.

Conclusion

Expressa Configurator is not merely a faster renderer – it is a strategic enabler of modern aircraft interior businesses. By tightly integrating design, engineering and sales workflows into one real-time platform, it transforms how clients engage with cabin design. High-fidelity visuals and instant configurability keep customers actively involved, speeding up decision-making and deepening trust. As one industry leader notes, tools like Expressa Configurator have become “much more important” in today’s accelerated market, letting companies showcase advanced options without leaving the office. In the ultra-competitive VVIP and business-jet space, the ability to interact with a live 3D cabin model – tweaking colors, fabrics and layouts on demand – can be the difference between a closed sale and a lost opportunity.

By extending the same real-time, photoreal approach to sales and marketing, Expressa helps OEMs impress clients early in the sales journey and reinforce brand excellence.

In summary, Expressa Configurator redefines 3D visualization for ultra-luxury aircraft interiors. It not only addresses every traditional bottleneck (from material fidelity to review delays) but does so in a way that amplifies client engagement and accelerates market responsiveness. For OEMs, MROs and design teams, adopting a tool like the Expressa Configurator can turn cabin personalization from a slow, costly hassle into a seamless, revenue-driving competitive advantage.

Image sources: Expressa Configurator 1.6 by KiPcreating